INTERESTING ACTIVITIES

CANE MILL RESTORATION AND SYRUP MAKIN'

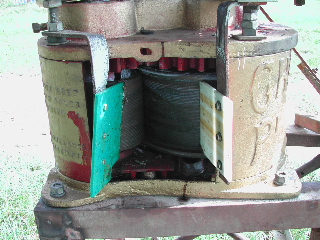

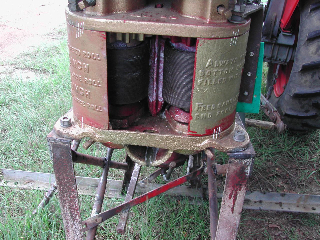

"IMPROVED" CANE MILL

Was in fairly good shape except for all three bottom bearings and shafts.

Shafts were welded-up and turned-down.

Bottom 3 bearings were replaced with used brass bushings left over from excavator repairs.

They fit perfectly.

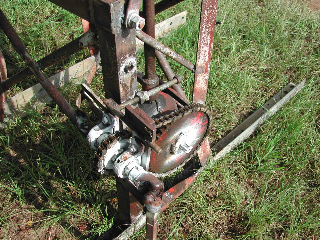

Plastic scrapers work great  Small sprocket has clutch built in. 3.9:1 ratio peanut inverter gearbox  Bagasse, 98% juice free  6.5 RPM at tractor idle |

#80 chain  Shields up / Osha approved  Flow too clear to see  It's juice! |

The "power" conversion was made doable as a result of decades of gathering parts for chufa harvester construction.

Square part of main shaft was turned down to fit a recycled 54 tooth #80 sprocket. Still, a huge investment in time just to get rid of a mule/riding lawn mower operator. All for 1/20 acre of sugar cane from stubble which made 100 gal of juice in '08, cooked down to 10 gal of syrup in a 60 gal kettle using wood.

A major disadvantage is that this setup is dependent on "high tech" bearings.

We intend to create some method on the big sprocket for re-attaching "the pole" while electricity and oxy/actl is still available. And maybe add a 3pt. hitch arch so it can be moved with tractor. This would make for easy transport and the mill could be moved instead of moving the bagasse. With the addition of a portable storage tank, it could be operated in the cane field, negating the need to load and haul the cane to the mill.

Square part of main shaft was turned down to fit a recycled 54 tooth #80 sprocket. Still, a huge investment in time just to get rid of a mule/riding lawn mower operator. All for 1/20 acre of sugar cane from stubble which made 100 gal of juice in '08, cooked down to 10 gal of syrup in a 60 gal kettle using wood.

A major disadvantage is that this setup is dependent on "high tech" bearings.

We intend to create some method on the big sprocket for re-attaching "the pole" while electricity and oxy/actl is still available. And maybe add a 3pt. hitch arch so it can be moved with tractor. This would make for easy transport and the mill could be moved instead of moving the bagasse. With the addition of a portable storage tank, it could be operated in the cane field, negating the need to load and haul the cane to the mill.